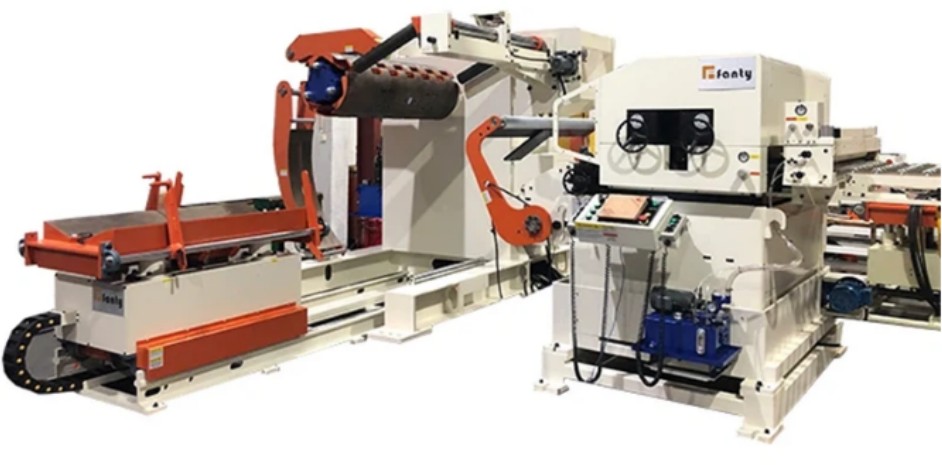

Decoilers play a crucial role in various industrial processes, facilitating the smooth unwinding of coiled materials such as metal sheets, wires, or cables. Understanding the difference between a coiler and a decoiler is essential for optimizing production efficiency and ensuring the seamless flow of materials. In this article, we delve into the intricacies of decoilers, exploring their functions, types, and significance in industrial settings.

Understanding Decoilers:

Decoilers, also known as uncoiler, serve as indispensable components in manufacturing facilities where coiled materials are utilized. Unlike coilers, which wind materials into coils, decoilers are responsible for unwinding these coils, preparing them for further processing. This distinction highlights the complementary nature of coilers and decoilers in material handling processes.

Functions of Decoilers:

The primary function of a decoiler is to ensure the controlled and steady unwinding of coiled materials. This process is essential for maintaining production efficiency and preventing material wastage. Decoilers are equipped with mechanisms such as tension control systems and loop control devices to regulate the unwinding process, ensuring consistent material feed to downstream operations.

Types of Decoilers:

Decoilers come in various types and configurations to accommodate different types of coiled materials and production requirements. Some common types of decoilers include motorized decoilers, hydraulic decoilers, and pneumatic decoilers. Motorized decoilers utilize electric motors to drive the unwinding process, offering precise control and high-speed operation. Hydraulic decoilers employ hydraulic systems for smooth and powerful unwinding, suitable for handling heavy-duty materials. Pneumatic decoilers utilize compressed air to drive the unwinding mechanism, offering flexibility and energy efficiency.

Importance of Decoilers in Industrial Processes:

Decoilers play a critical role in ensuring the efficiency and productivity of industrial processes that involve coiled materials. By providing a seamless unwinding mechanism, decoilers enable continuous production without interruptions or delays. This contributes to overall cost-effectiveness and competitiveness in the manufacturing sector. Additionally, decoilers help minimize material waste and reduce the risk of accidents associated with manual handling of coiled materials.

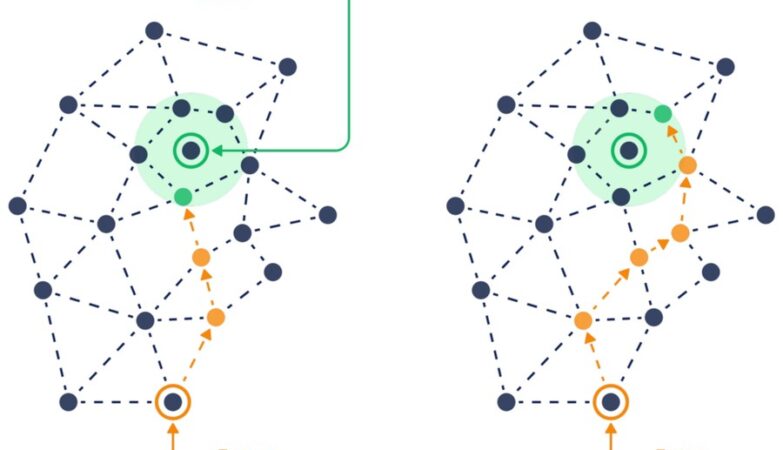

Integration with Automation Systems:

In modern manufacturing facilities, decoilers are often integrated into automation systems to enhance efficiency and reduce labor requirements. Automated decoiling systems can be programmed to adjust tension levels, control material feed rates, and communicate with other equipment in the production line. This level of automation not only improves productivity but also ensures consistency and quality in the manufacturing process.

Maintenance and Care of Decoilers:

Proper maintenance and care are essential to ensure the optimal performance and longevity of decoilers. Regular inspection of mechanical components, lubrication of moving parts, and calibration of control systems are necessary to prevent downtime and costly repairs. Additionally, operators should receive adequate training in operating and troubleshooting decoilers to address any issues promptly and minimize production disruptions.

Future Trends in Decoiler Technology:

As manufacturing processes continue to evolve, so will the technology associated with decoilers. Advancements in automation, robotics, and materials science are expected to drive innovations in decoiler design and functionality. Future decoilers may feature advanced sensors for real-time monitoring, predictive maintenance capabilities, and enhanced integration with digital manufacturing systems. These developments will further streamline production processes and improve overall efficiency in industrial settings.

Conclusion:

Decoilers play a vital role in the seamless handling of coiled materials in industrial processes. By facilitating controlled unwinding and material feed, decoilers contribute to increased productivity, reduced waste, and improved quality in manufacturing operations. Understanding the differences between coilers and decoilers is essential for optimizing production efficiency and ensuring the smooth flow of materials throughout the manufacturing process. As technology continues to advance, decoilers will remain integral components of modern manufacturing facilities, driving innovation and efficiency in material handling processes.